Lowering your truck offers a head-turning aesthetic and improved handling, but it also throws a wrench into the factory suspension's carefully engineered balance. Suddenly, your shocks are working outside their intended range, leading to a bouncy, uncomfortable ride, and potentially compromising safety. Choosing the right shocks for your lowered truck is therefore crucial for maintaining ride quality, handling performance, and overall driving enjoyment. This comprehensive guide will delve into the world of shocks designed specifically for lowered trucks, helping you navigate the options and make an informed decision.

Why Upgrading Shocks is Essential for Lowered Trucks

Best Shocks For Lowered Trucks: Ride Quality, Performance, and Everything In Between

Factory shocks are designed to work within a specific range of suspension travel. Lowering your truck reduces this travel, forcing the shocks to operate outside their optimal zone. This can lead to several issues:

- Bottoming Out: Reduced travel increases the likelihood of the suspension bottoming out, resulting in harsh impacts and potential damage to the chassis and other components.

- Poor Ride Quality: Factory shocks often become overly stiff and uncomfortable when lowered, transmitting every bump and imperfection in the road directly to the cabin.

- Reduced Handling: Inadequate shock damping can lead to excessive body roll, poor steering response, and decreased stability, especially during cornering and emergency maneuvers.

- Premature Wear: Operating outside their intended range can accelerate wear and tear on factory shocks, leading to premature failure.

Upgrading to shocks specifically designed for lowered trucks addresses these issues by providing:

- Optimized Damping: Lowered truck shocks are tuned to control the suspension movement within the reduced travel range, providing a smoother, more controlled ride.

- Proper Travel: Many aftermarket shocks offer a shorter overall length and travel range to prevent bottoming out and ensure proper function within the lowered suspension setup.

- Improved Handling: Enhanced damping characteristics improve steering response, reduce body roll, and enhance overall stability, leading to a more confident and enjoyable driving experience.

- Increased Durability: Many aftermarket shocks are built with higher-quality materials and construction, ensuring long-lasting performance and reliability.

Types of Shocks for Lowered Trucks

Choosing the right shocks for your lowered truck requires understanding the different types available and their respective characteristics:

- Twin-Tube Shocks: These are the most common type of shock absorber, offering a balance of performance and affordability. They consist of two concentric tubes, with hydraulic fluid flowing between them to dampen suspension movement. While suitable for mild lowering setups, they may not offer the best performance for more aggressive drops or performance-oriented driving.

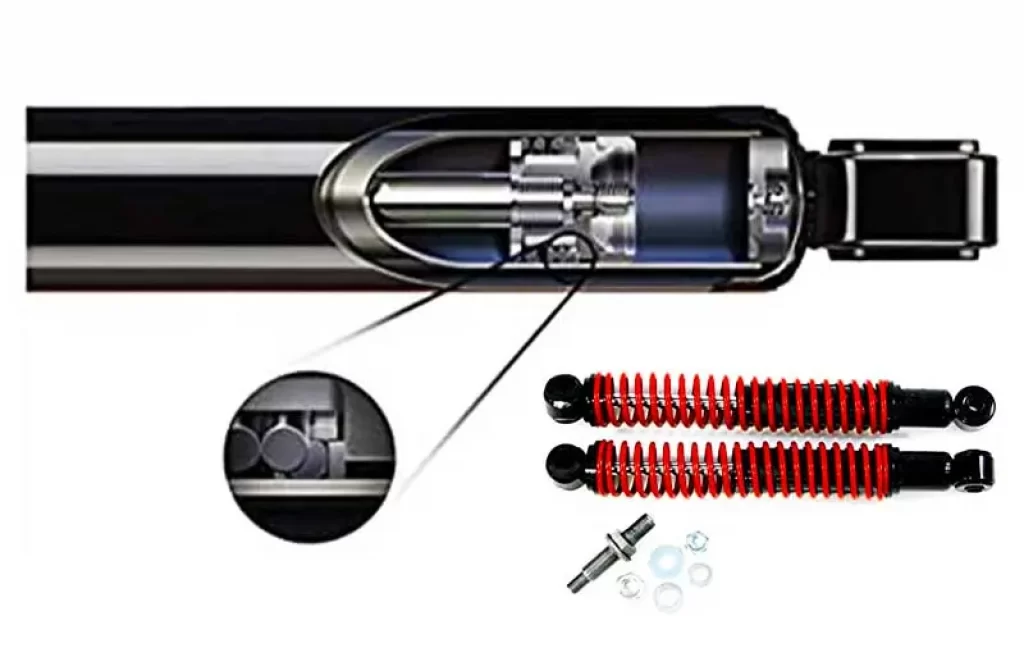

- Mono-Tube Shocks: Mono-tube shocks feature a single tube containing the hydraulic fluid and a floating piston. This design offers several advantages over twin-tube shocks, including better heat dissipation, faster response times, and improved damping performance. They are a popular choice for lowered trucks that require enhanced handling and control.

- Adjustable Shocks: Adjustable shocks allow you to fine-tune the damping characteristics to match your driving style and road conditions. They typically offer multiple settings for compression (resistance to upward movement) and rebound (resistance to downward movement), allowing you to dial in the perfect ride quality and handling balance. These are ideal for enthusiasts who want maximum control over their suspension.

- Single Adjustable: Allows adjustment of both compression and rebound with a single knob, simplifying the tuning process.

- Double Adjustable: Provides independent adjustment of compression and rebound, offering more precise control over the suspension.

- Air Shocks: While not solely designed for lowering, air shocks can be used to adjust ride height and load-carrying capacity. They use compressed air to provide damping and support, allowing you to compensate for varying loads and maintain a level ride height. However, they typically don't offer the same level of performance as dedicated lowered truck shocks.

- Coilovers: While technically a complete suspension unit, coilovers are a popular upgrade for lowered trucks. They combine a shock absorber and a coil spring into a single unit, allowing for adjustable ride height and damping. Coilovers offer the ultimate in performance and customization, but they are also the most expensive option.

Key Considerations When Choosing Shocks

Selecting the right shocks for your lowered truck involves considering several factors:

- Lowering Amount: The amount of lowering will dictate the required shock travel and length. Measure the distance between the upper and lower shock mounts at your desired ride height to determine the appropriate shock length.

- Driving Style: Consider how you primarily use your truck. If you prioritize comfort and daily driving, twin-tube or adjustable shocks with softer damping settings may be suitable. If you demand maximum performance and handling, mono-tube or coilover shocks with more aggressive damping are a better choice.

- Budget: Shock prices can vary significantly depending on the type, features, and brand. Set a budget and stick to it, but don't compromise on quality, as shocks are a critical component of your suspension system.

- Compatibility: Ensure the shocks you choose are compatible with your truck's make, model, and year. Check the manufacturer's specifications and consult with a qualified suspension specialist if needed.

- Adjustability: If you want the ability to fine-tune your suspension, consider adjustable shocks. However, be prepared to spend time experimenting with different settings to find the optimal balance.

- Brand Reputation: Research different shock brands and read reviews from other truck owners. Choose a reputable brand known for quality, performance, and durability.

Installation Tips and Considerations

Installing new shocks on your lowered truck is a relatively straightforward process, but it's essential to follow these tips:

- Safety First: Always use jack stands to support the truck before working on the suspension.

- Proper Tools: Gather all the necessary tools, including wrenches, sockets, a torque wrench, and potentially a spring compressor (for coilovers).

- Consult the Manual: Refer to the manufacturer's instructions for specific installation procedures and torque specifications.

- Grease Fittings: If your shocks have grease fittings, be sure to lubricate them before installation.

- Torque Specifications: Torque all bolts and nuts to the manufacturer's specified torque values to ensure proper and safe installation.

- Professional Installation: If you're not comfortable performing the installation yourself, seek the assistance of a qualified mechanic.

- Alignment: After installing new shocks, it's crucial to have your truck's alignment checked and adjusted. Lowering the suspension can significantly affect the alignment angles, leading to premature tire wear and poor handling.

Potential Challenges and Solutions

Lowering your truck and upgrading the shocks can sometimes present challenges:

- Clearance Issues: Lowering the truck can reduce ground clearance, potentially leading to scraping or bottoming out on speed bumps or uneven terrain. Consider using shorter bump stops or adjustable air springs to mitigate this issue.

- Driveline Vibrations: Lowering the truck can alter the driveline angles, potentially causing vibrations. Installing a carrier bearing drop kit or adjustable control arms can help correct the driveline angles and eliminate vibrations.

- Ride Quality Compromises: While aftermarket shocks improve ride quality compared to factory shocks on a lowered truck, you may still experience a firmer ride than you're accustomed to. Experiment with different damping settings (if applicable) and consider using softer springs to fine-tune the ride quality.

Price Table of Shocks For Lowered Trucks

| Shock Type | Brand | Model | Vehicle Type | Key Features | Price Range (USD) |

|---|---|---|---|---|---|

| Twin-Tube | Monroe | Gas-Magnum 65 | Truck/SUV | Heavy-duty, Gas-charged | $40 - $80 per shock |

| Twin-Tube | KYB | Gas-a-Just | Truck/SUV | High-pressure gas, Improved handling | $50 - $90 per shock |

| Mono-Tube | Bilstein | 5100 Series | Truck/SUV | Zinc plated finish, Monotube design, Height adjustable | $100 - $150 per shock |

| Mono-Tube | Fox | 2.0 Performance Series | Truck/SUV | Aluminum body, Monotube design, Rebuildable | $150 - $250 per shock |

| Adjustable | QA1 | Single Adjustable | Truck/SUV | 18-position adjustability, Aluminum | $200 - $350 per shock |

| Adjustable | Ridetech | HQ Series | Truck/SUV | Adjustable rebound, Aluminum, Impact forged | $300 - $500 per shock |

| Coilover | Viking | Warrior | Truck/SUV | Adjustable ride height, Adjustable damping, Lightweight | $600 - $1000 per set |

| Coilover | KW Suspension | Variant 3 | Truck/SUV | Adjustable compression and rebound, Stainless steel | $2000 - $4000 per set |

| Air Shock | Air Lift Company | 1000 Universal Air Spring Kit | Truck/SUV | Adjustable load support, Improves ride quality while towing | $100 - $200 per kit |

Frequently Asked Questions (FAQ)

- Q: Will lowering my truck void the warranty?

- A: Lowering your truck can void certain parts of your warranty, particularly those related to the suspension and driveline. Consult your warranty documentation and speak with your dealer for clarification.

- Q: How often should I replace my shocks?

- A: Shock life depends on driving conditions and usage. However, it's generally recommended to replace shocks every 50,000 to 75,000 miles, or sooner if you notice signs of wear, such as excessive bouncing or leaking fluid.

- Q: Can I use factory shocks on a lowered truck?

- A: While you can use factory shocks on a mildly lowered truck, it's not recommended. Factory shocks are not designed to operate within the reduced travel range, leading to poor ride quality and premature wear.

- Q: What's the difference between compression and rebound damping?

- A: Compression damping controls the resistance to upward movement of the suspension, while rebound damping controls the resistance to downward movement. Adjusting these settings can fine-tune the ride quality and handling balance.

- Q: Do I need to get an alignment after installing new shocks?

- A: Yes, it's highly recommended to get an alignment after installing new shocks, especially if you've lowered your truck. Lowering the suspension can significantly affect the alignment angles, leading to premature tire wear and poor handling.

Conclusion

Choosing the best shocks for your lowered truck is a critical step in maintaining ride quality, handling performance, and overall driving enjoyment. By understanding the different types of shocks available, considering your driving style and budget, and following the installation tips outlined in this guide, you can ensure that your lowered truck rides and handles as good as it looks. Remember to prioritize safety and consult with a qualified suspension specialist if needed. Ultimately, the right shocks will transform your lowered truck from a head-turner into a truly enjoyable and well-performing vehicle.