Introduction: The Lightweight Revolution in Classic Truck Restoration

The Chevrolet truck, a symbol of American grit and utility, has been a mainstay on roads and job sites for generations. While the classic steel bodies are iconic, they are also prone to rust, dents, and the general wear and tear that comes with age. Enter the fiberglass Chevy truck body – a modern solution for restoring, customizing, or even building a classic Chevy truck from the ground up. Fiberglass bodies offer a compelling alternative, providing a lightweight, durable, and rust-resistant platform for your project. This article delves into the world of fiberglass Chevy truck bodies, exploring their benefits, installation considerations, types, and everything else you need to know to decide if this is the right path for your truck project.

Fiberglass Chevy Truck Body: A Comprehensive Guide

I. Why Choose a Fiberglass Chevy Truck Body? The Advantages

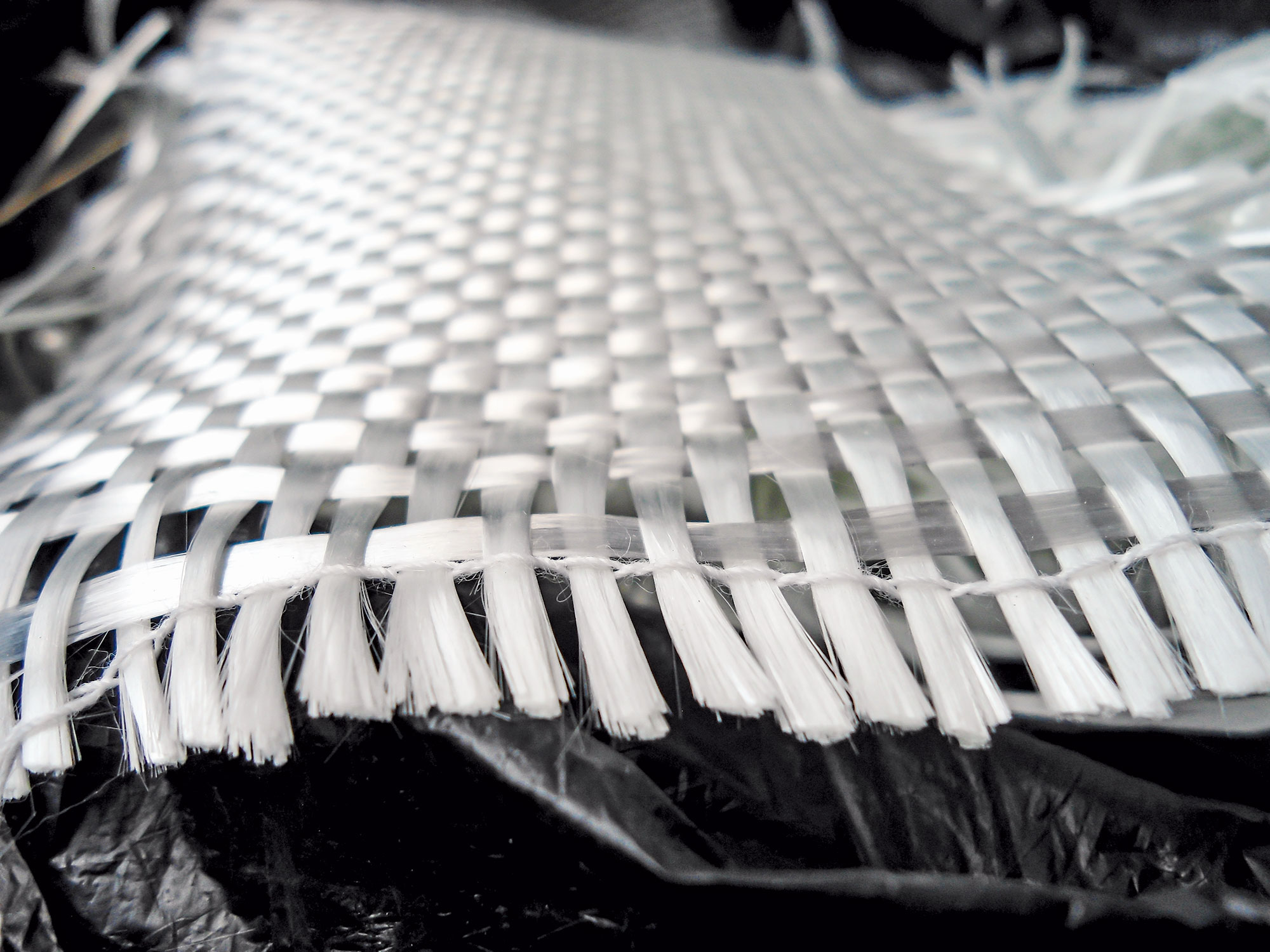

Fiberglass, or Glass Reinforced Plastic (GRP), is a composite material made by embedding glass fibers in a resin matrix. This combination yields a material with exceptional strength-to-weight ratio, making it ideal for automotive applications. Here's a breakdown of the key advantages of using a fiberglass body for your Chevy truck:

- Rust Resistance: This is arguably the biggest selling point. Unlike steel, fiberglass is impervious to rust. This significantly reduces maintenance and extends the life of your truck, especially in regions with harsh weather conditions or salty roads.

- Lightweight: Fiberglass is considerably lighter than steel. A lighter body improves fuel efficiency, acceleration, and handling. This is particularly beneficial for trucks used for racing or off-roading.

- Durability: While not as impact-resistant as steel in a direct collision, fiberglass is surprisingly durable and resistant to dents. Minor dings and scratches are less likely to occur compared to a steel body.

- Ease of Repair: Fiberglass is relatively easy to repair using readily available materials and techniques. Cracks and chips can be patched and sanded smooth, restoring the body to its original condition.

- Customization Potential: Fiberglass is easily molded and shaped, allowing for a wide range of customization options. From custom fender flares to unique body lines, fiberglass opens up endless possibilities for creating a one-of-a-kind truck.

- Cost-Effectiveness (Long Term): While the initial cost of a fiberglass body might be higher than repairing a steel body, the long-term savings in rust repair, reduced weight (better fuel economy), and easier maintenance often make it a cost-effective choice.

II. Fiberglass Chevy Truck Body Types and Styles

Fiberglass Chevy truck bodies are available in a variety of styles to suit different tastes and project goals. Here's a look at some common types:

- Complete Body Shells: These are direct replacements for the original steel body, including the cab, bed, and sometimes even the front clip (hood and fenders). They are designed to bolt directly onto the original chassis.

- Cab Only: If your existing bed is in good condition, you can opt for a fiberglass cab only. This is a popular choice for restoring trucks with severe cab rust but a salvageable bed.

- Bed Only: Conversely, if your cab is solid but the bed is rusted beyond repair, a fiberglass bed is a great option. These beds are often designed to mimic the original steel beds, complete with correct dimensions and details.

- Front Clip (Hood and Fenders): A front clip is a set of body panels including the hood, and fenders. Fiberglass front clips reduce weight and improve performance.

- Custom Bodies: These are not replicas of original bodies but are designed for specific purposes, such as off-road racing or show trucks. They often feature unique body lines, integrated roll cages, and other performance-enhancing features.

- Styles and Generations:

- 1947-1954 (Advance Design): Classic curves and iconic styling.

- 1955-1959 (Task Force): A more modern look with wraparound windshields.

- 1960-1966 (C/K Series): A popular generation with a distinctive body style.

- 1967-1972 (C/K Series): Known for their clean lines and comfortable ride.

- 1973-1987 (Square Body): A rugged and boxy design that is still popular today.

.jpg)

III. Installation Considerations: Preparing for the Switch

Installing a fiberglass Chevy truck body is a significant undertaking, but with proper planning and execution, it can be a rewarding experience. Here are some key considerations:

- Chassis Condition: Ensure your truck's chassis is in good condition. Repair any rust or damage before installing the new body. A solid foundation is crucial for a safe and reliable vehicle.

- Fitment and Alignment: Fiberglass bodies are generally designed to be a direct fit, but minor adjustments may be necessary. Check the fitment of the body panels before final installation. Shimming and trimming may be required to achieve proper alignment.

- Wiring and Plumbing: Transferring the wiring harness and plumbing lines from the old body to the new one can be time-consuming. Take detailed photos and label all wires and hoses to ensure proper reinstallation.

- Interior Components: Plan how you will reinstall the interior components, such as the seats, dashboard, and door panels. Some modifications may be necessary to fit these components into the fiberglass body.

- Professional Help: If you're not comfortable with complex automotive projects, consider hiring a professional to install the fiberglass body. This will ensure the job is done correctly and safely.

- Paint and Finish: Fiberglass bodies typically come in a gel coat finish, which is a protective layer that needs to be sanded and prepped before painting. Use high-quality automotive paint and clear coat for a durable and long-lasting finish.

IV. Practical Tips and Tricks for a Successful Installation

- Dry Fit Everything: Before applying any adhesives or fasteners, dry fit all the body panels to ensure proper alignment and fitment.

- Use Quality Adhesives and Sealants: Choose high-quality adhesives and sealants specifically designed for fiberglass. This will ensure a strong and durable bond.

- Reinforce Stress Points: Reinforce areas that are subject to stress, such as mounting points and door hinges, with additional fiberglass or metal plates.

- Take Your Time: Don't rush the installation process. Take your time and pay attention to detail to ensure a professional-quality result.

- Document Everything: Take photos and notes throughout the installation process. This will be helpful if you need to troubleshoot any problems or refer back to the installation process in the future.

- Safety First: Wear appropriate safety gear, such as gloves, eye protection, and a respirator, when working with fiberglass.

V. Potential Challenges and Solutions

- Fitment Issues: Fiberglass bodies are not always a perfect fit. Be prepared to make minor adjustments to ensure proper alignment.

- Solution: Use shims, spacers, and a body hammer to adjust the fitment of the body panels.

- Surface Imperfections: Fiberglass bodies may have minor surface imperfections, such as pinholes or gel coat cracks.

- Solution: Fill these imperfections with body filler and sand smooth before painting.

- Wiring and Plumbing Complications: Transferring the wiring harness and plumbing lines can be challenging.

- Solution: Label all wires and hoses carefully and refer to a wiring diagram if necessary.

- Lack of Structural Support: Fiberglass bodies may not be as strong as steel bodies in certain areas.

- Solution: Reinforce stress points with additional fiberglass or metal plates.

- Cost: Fiberglass bodies can be expensive.

- Solution: Shop around for the best prices and consider purchasing a used fiberglass body.

VI. Maintaining Your Fiberglass Chevy Truck Body

- Regular Washing: Wash your truck regularly with mild soap and water to remove dirt and grime.

- Waxing: Apply a coat of wax every few months to protect the paint and keep it looking shiny.

- Inspect for Damage: Regularly inspect the body for cracks, chips, or other damage. Repair any damage promptly to prevent it from spreading.

- Avoid Harsh Chemicals: Avoid using harsh chemicals or abrasive cleaners on the fiberglass body.

- Store Indoors: If possible, store your truck indoors to protect it from the elements.

VII. Price Table of Fiberglass Chevy Truck Body

| Product Description | Brand/Manufacturer (Example) | Approximate Price (USD) | Additional Notes |

|---|---|---|---|

| Complete Fiberglass Body Shell (1967-1972 C10) | Dynacorn | $8,000 - $12,000 | Includes cab and bed. Price varies based on features (e.g., inner fenders). |

| Fiberglass Cab Only (1955-1959 Task Force) | US Body Source | $4,500 - $7,000 | Some assembly may be required. |

| Fiberglass Bed Only (1960-1966 C10) | Auto Metal Direct | $2,500 - $4,000 | Can be ordered with or without wood bed floor. |

| Fiberglass Front Clip (1973-1987 Square Body) | VFN Fiberglass | $1,800 - $3,000 | Lightweight option for racing or performance applications. |

| Custom Fiberglass Body (Off-Road Racing) | Hannemann Fiberglass | $10,000+ | Prices vary significantly depending on design complexity and features. |

| Complete Fiberglass Body Shell (1947-1954 Advance Design) | Brookville Roadster | $9,000 - $13,000 | Includes cab and bed. Price varies based on features (e.g., inner fenders). |

VIII. Frequently Asked Questions (FAQ)

- Q: Are fiberglass truck bodies street legal?

- A: Yes, fiberglass truck bodies are generally street legal, provided they meet all applicable safety regulations. Check with your local authorities for specific requirements.

- Q: Can I paint a fiberglass truck body myself?

- A: Yes, you can paint a fiberglass truck body yourself, but it requires proper preparation and technique. It's recommended to have some experience with automotive painting before attempting this project.

- Q: How long does it take to install a fiberglass truck body?

- A: The installation time can vary depending on the complexity of the project and your level of experience. A complete body swap can take anywhere from a few days to a few weeks.

- Q: Do I need any special tools to install a fiberglass truck body?

- A: You will need basic hand tools, as well as some specialized tools such as a body hammer, sanding blocks, and a fiberglass repair kit.

- Q: Where can I buy a fiberglass Chevy truck body?

- A: Fiberglass Chevy truck bodies are available from a variety of sources, including aftermarket parts suppliers, online retailers, and specialty fiberglass manufacturers.

- Q: Can I use my original hardware with a fiberglass body?

- A: In most cases, yes, you can reuse your original hardware. However, it's a good idea to replace any worn or damaged hardware with new components.

Conclusion: A Modern Solution for a Classic Truck

Fiberglass Chevy truck bodies offer a compelling alternative to traditional steel bodies, providing a lightweight, rust-resistant, and customizable platform for your restoration or customization project. While the installation process requires careful planning and execution, the benefits of a fiberglass body – including improved performance, reduced maintenance, and enhanced longevity – make it a worthwhile investment for many truck enthusiasts. Whether you're restoring a classic Chevy truck or building a custom off-road machine, a fiberglass body can help you achieve your vision and create a truly unique vehicle. Weigh the advantages and disadvantages, consider your budget and skill level, and decide if a fiberglass Chevy truck body is the right choice for your next project.